Helium compressor / noble gases

Argon compaction in a thermic processing plant for high-quality materials

Starting position / boundary conditions

In the heat treatment of materials, people like to work with inert gas such as helium, argon or nitrogen. When using noble gases, the systems are connected with a gas recovery.

In reference example, our client is a German engineering company which had built a thermo-technical process plant for high-quality materials in Brazil. In this project, the customer had originally used an air compressor, which was made "gas-tight" for use with Argon. The test mode found out that the compressor was not gas-tight. Atmospheric oxygen entered via the compressor into the system, which is not allowed for the heat treatment.

Requirements

The customer operates its system with argon. It is prescribed that no air enters the system and thus influences not the heat treatment.

Argon is available at 0.5 bar suction pressure. The maximum discharge pressure is at around 5 bar.

The compressor is integrated by system manufacturers and controlled and monitored via a control system.

The compressors have to be oil-free and have to be designed for continuous operation. Demanded are reliable and maintenance-friendly compressors.

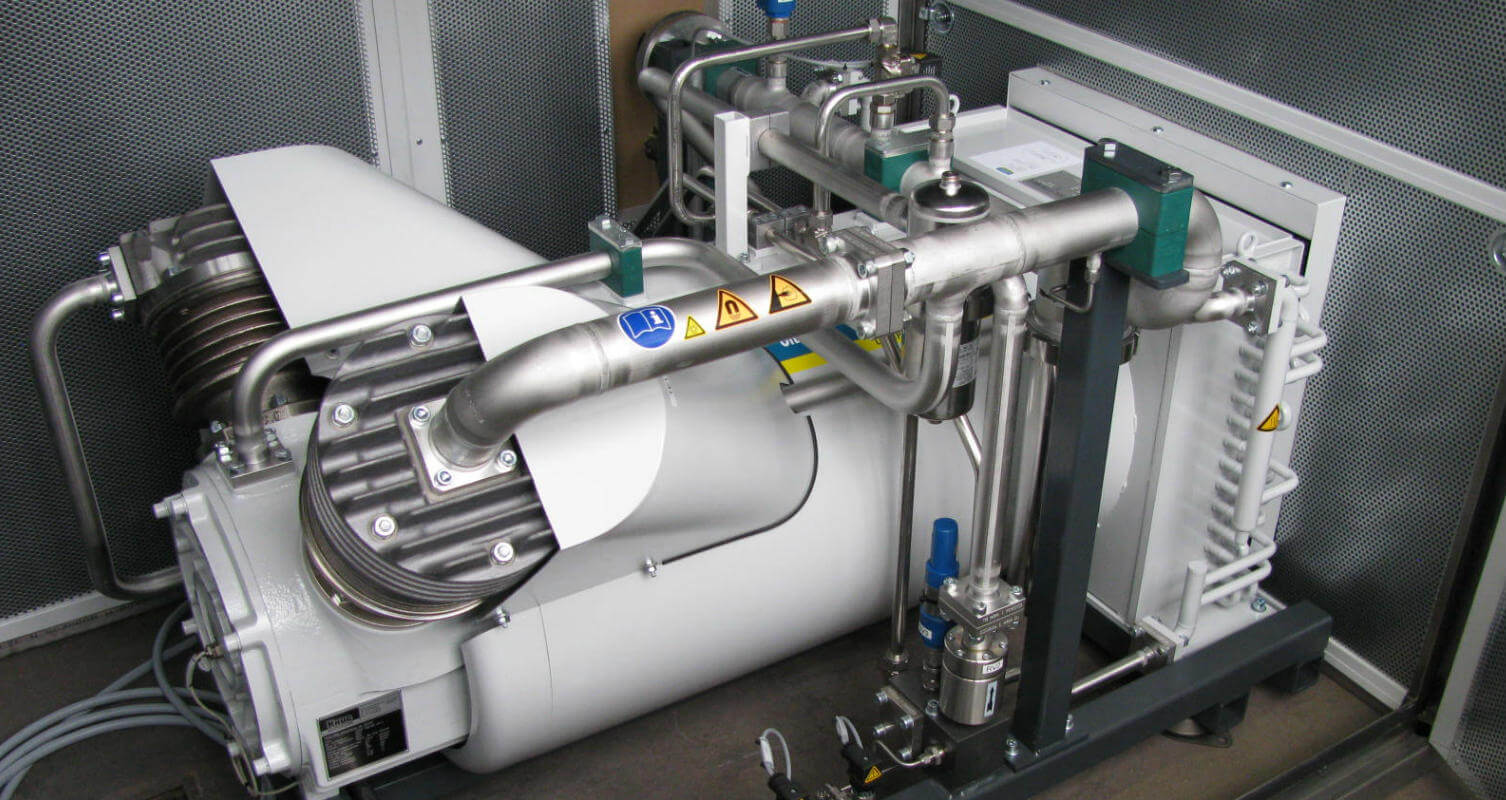

HAUG Sauer solution

HAUG Sauer provided a 2-stage compressor Sirius type with a flow rate of about 100 Nm3/h. The scope of supply includes the compressor with a sound hood.

The problems with the oxygen entry in the process were solved with the HAUG compressor immediately.

The key arguments for HAUG Sauer were: high reliability and easy maintenance, oil-free, absolute gas-tightness during operation or when stopped, personalized solution for the customer.

Helium applications in leak testing & Metalworking

Helium is a very rare and expensive gas. It is worthwhile recovering helium after use and reusing it.

The helium gas recovery takes place, for example in the industry in the leak test, in hardening processes in the metal industry, in the frozen technology, in the use as a process gas in industry and in numerous applications in research.

The helium is collected at the highest possible pressure in a container and compressed subsequently by a compressor to the desired storage pressure. The plants are working in a closed circuit. Only spent helium must be supplied. This saves a good part of the expensive helium.

The gas-tightness of the processes and gas purity are important in the recovery system. Contamination by gas leaks into the environment. will falsify leak-test measurements. During heat treatment with helium, impurities in the helium will lead to errors and a reduction in the quality of the heat treatment process.

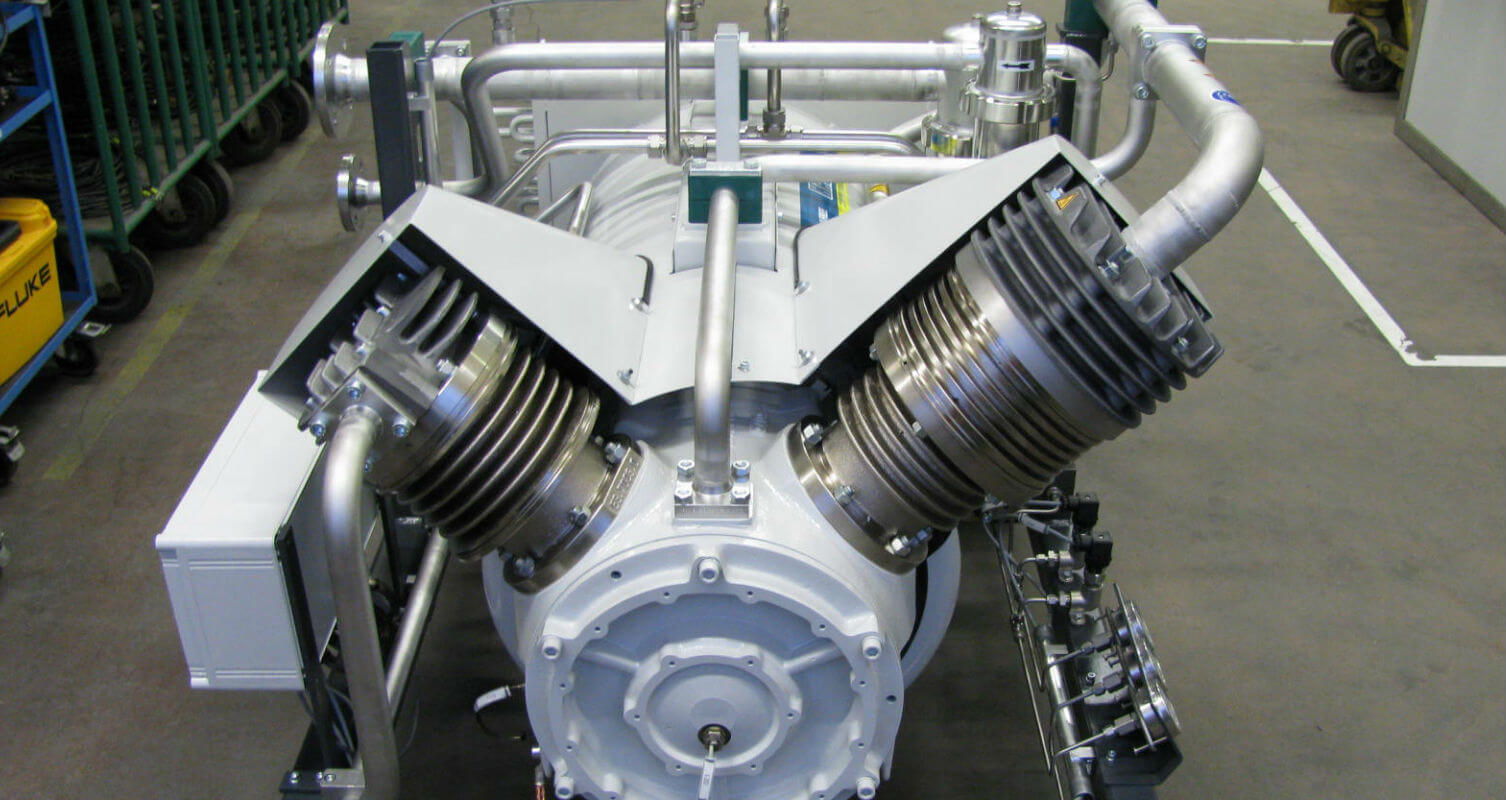

Technical advantages of the HAUG compressors

HAUG piston compressors have the best conditions for inert gas applications thanks to their oil-free, dry-running and gas-tight design.

- no gas pollution by oil

- technically sealed, in operation or when stopped

- flexible regarding variable suction and discharge pressure