Gas recompression

OEM compressors for gas recompression

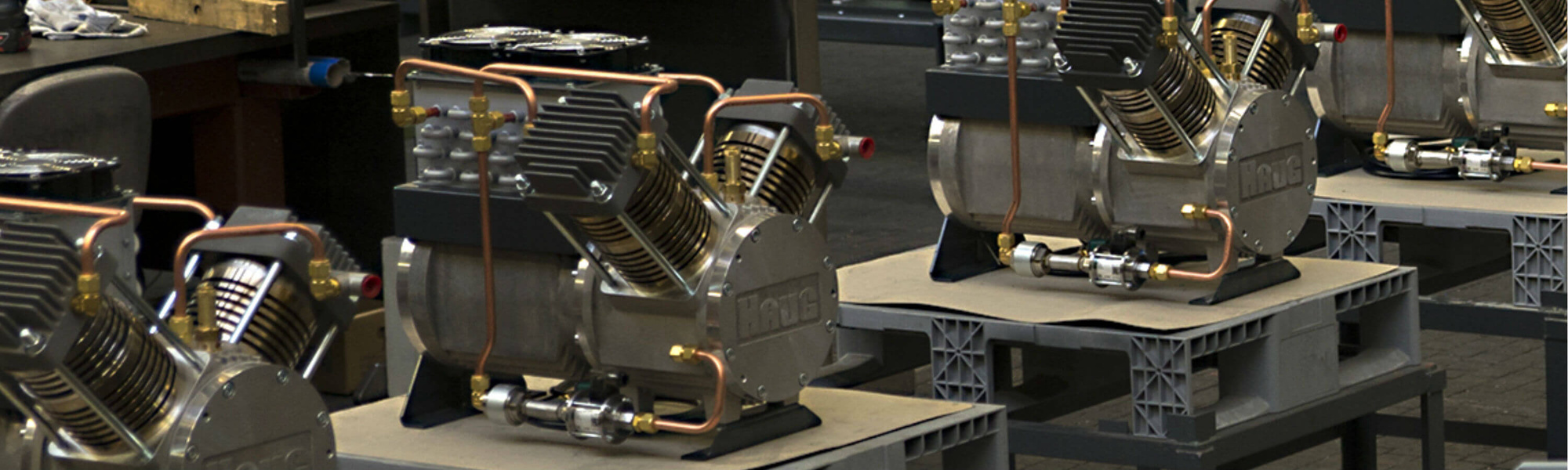

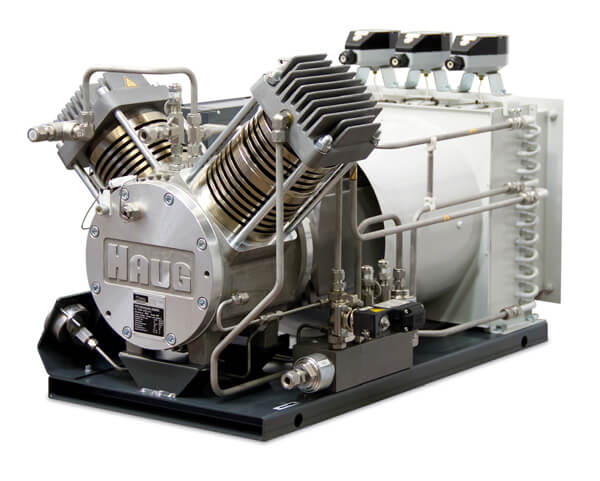

«OEM compressors» are standard compressors, individually optimised for "OEM customers". "OEM customers" benefit from a cost-optimised and individual compressor. Compressors are produced for "OEM customers" in larger quantities and frame orders.

Features of OEM compressors for gas recompression

OEM compressors for gas recompression are based on HAUG Sauer core competencies:

- Completely oil-free and dry running

- High reliability for continuous and intermittent operation

- Permanently hermetically gas-tight

- Innovative solutions tailored to the individual needs of OEM customers

- Cost optimised series solutions and individual project-specific solutions

Scope of delivery of OEM compressors for gas recompression

The compressors are integrated by the OEM in an OEM system. The gas preparation before and after the compressor is made by the OEM. The control and monitoring of the compressor is ensured either by a control unit built on the compressor or by a central control unit of the OEM system. The compressor scope of delivery is either only compressor block with a base equipment or a complete compressor system with a control unit.

Applications of OEM compressors gas recompression

- Recompression of compressed air, for example, as an instrument air for emergency care, as a pneumatic drive air or for medical compressed air supply

- Recompression of nitrogen, for example, after a PSA plant or from a nitrogen-network

- Recompression of oxygen, for example, after a VPSA or PSA plant

- Recompression of hydrogen, for example, by an electrolysis system